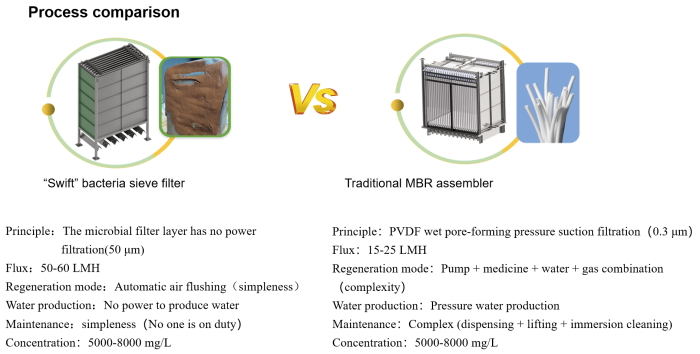

With the acceleration of urbanization and population growth, sewage treatment has become an important environmental protection work. In the field of sewage treatment, biochemical process (A/O, A2/O) +MBR combination technology has developed into a program presetting and integrated technology, the technical facility has the characteristics of program presetting, obvious effect, strong adaptability, convenient construction, etc., suitable for the treatment of distributed domestic sewage. However, MBR technology has high infrastructure investment in the early stage, high operating costs, and fluctuations in water volume according to the operating status of the membrane process, and is not fully used in all sewage treatment scenarios.

(1) High investment in infrastructure

The cost of MBR membrane is high, the service life is short, and the whole membrane system contains a lot of equipment, which makes the infrastructure investment of the MBR membrane process higher than that of the traditional secondary biological treatment process.

(2) High operating costs

The equipment used in the membrane process such as the membrane hair dryer and the water production pump leads to an increase in power consumption, in addition, the agent cost required to maintain the normal operation of the membrane flux is also relatively high, making the cost of the entire process operation higher.

(3) Uncertainty of water production

Because the whole membrane system contains more equipment, some equipment failure leads to a single or multiple membrane pool not producing water normally, the water production also decreases, and the use of water backwashing, online chemical cleaning and offline chemical cleaning to maintain the normal stability of the membrane flux, will also reduce the water production, the higher the cleaning frequency, the more obvious the water reduction.

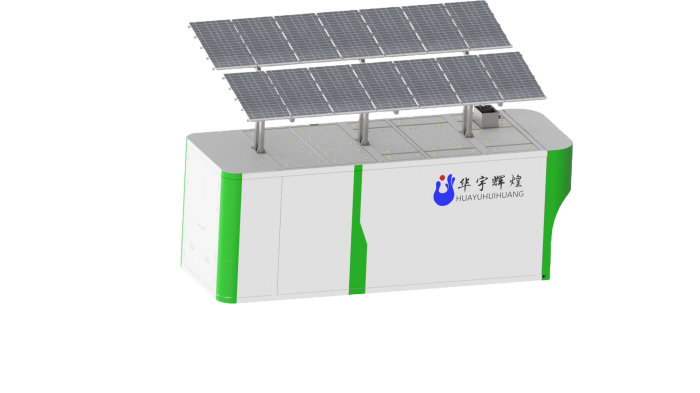

In response to the above problems, an integrated equipment suitable for decentralized sewage treatment was developed to meet the requirements of low energy consumption, low cost and high water quality standards. “Swift” Solar-Powered Sewage Treatment Bioreactor is a super energy-saving sewage treatment equipment suitable for distributed sewage treatment developed by Beijing Huayuhuihuang Eco-Environmental Protection Technology Co., Ltd. (HYHH) under the background of "double carbon", with a treatment scale of 10-150 tons/day.

This equipment has a major technological breakthrough in energy consumption and process, first of all, in terms of energy consumption than the traditional MBR membrane process of the integrated equipment reduced by more than 50%, can be equipped with solar photovoltaic power generation panels and energy storage batteries, green energy substitute or supplement the power consumption, reduce carbon emissions; In terms of process, a micron-level filtration membrane layer is formed by using microbial flora and EPS in activated sludge under the action of special base membrane and hydraulic flow state, to achieve efficient solid-liquid separation through microgravity water production, and achieve water quality standard discharge without sedimentation tank and advanced treatment, while improving sludge concentration and improving effluent effect.